Products

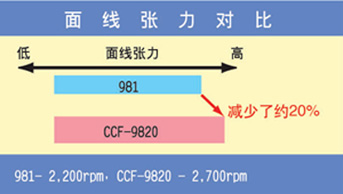

1.The maximum sewing speed of 2,700 rpm has been achievedby the adoption of an optimal machine structure for highspeeddrive.

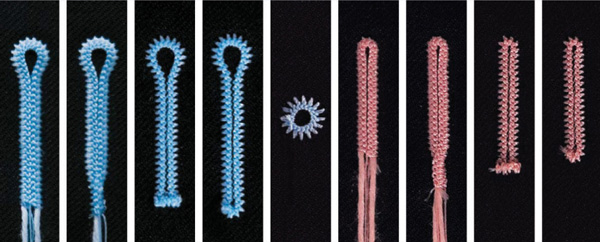

2.Skipped stitches are reduced

The shape of the looper,the thread take-up amount and some other parts have been reviewed.Skipped stitches and insufficient thread tightening due to a change of thread tension are reduced,regardless of types of threads.The range of sewing capability has been enlarged.

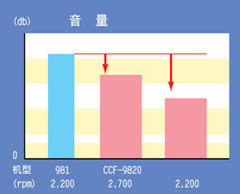

3.Sewing with less noise

With thorough review of the mechanisms causing noise,quieter sewing even at higher sewing speed than the conventional model has been realized.The machine is made with a sound design gentle to ears,eliminating impact noise.The vibration of the feed base which is transmitted to an operator is also reduced.The working environment with less operator fatigue can be materialized.

| |

| |

|

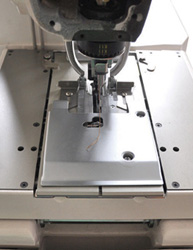

1.Large arm pocket providing ease 0f operation

The arm pocket of 120 mm depth gives a sufficient space,enabling material setting smooth.It is the most suitable for sewing of vertical buttonholes and hip pocket parts.The arm shape Provides a good view of the needle area.allowing operators to observe the sewi ng operation.

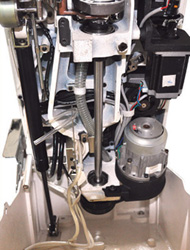

2.Economical model with lOW power consumption

With the adoption of a energy-saving compact motor,electric power consumption has been lowered by more than 35% compared with the conventional model.while enhancing Productivity with the improved max.sewing speed.The CCF-9820 is the most energy-saving electronic eyelet buttonhole sewing machine in the market.

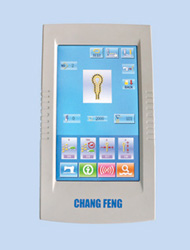

3.Operation panel easy to use for everyone

The CCF-9820 is equipped with a liquid crystal display(LCD) and indicates display iterns with icons and letters.Setting and check of sewing patterns and change of sewing modes are easy to understand and carry out.

|

|

|